image from: www.hotrod.com

Designing and building your own motorized projects—from electric bikes to small-scale engines—is one of the most rewarding hobbies out there. But without the right tools, even the best ideas can fall flat. Whether you’re a beginner or a seasoned builder, equipping your workspace with the top DIY motor design tools will dramatically improve your efficiency, accuracy, and results.

In this article, we’ll explore the must-have tools for DIY motor design, categorized by function, ease of use, and impact—so you can build smarter, safer, and more confidently.

Why the Right Tools Matter in Motor Design

Motor design is not just about creativity—it’s about precision, durability, and performance. The tools you use affect every phase of your project, from sketching your concept to assembling the final prototype. Using professional-grade or well-selected DIY tools ensures:

-

Accurate part alignment

-

Efficient workflow

-

Reduced material waste

-

Higher safety standards

Whether you’re crafting an electric motor, custom stator, or motor housing, the right equipment pays off in every detail.

Essential Tools for DIY Motor Design Projects

Here’s a breakdown of the most vital tools every hobbyist should consider:

1. Multimeter

A must-have for testing voltage, resistance, and continuity.

Why it matters: Ensures your circuits are functioning correctly and safely.

2. Digital Calipers

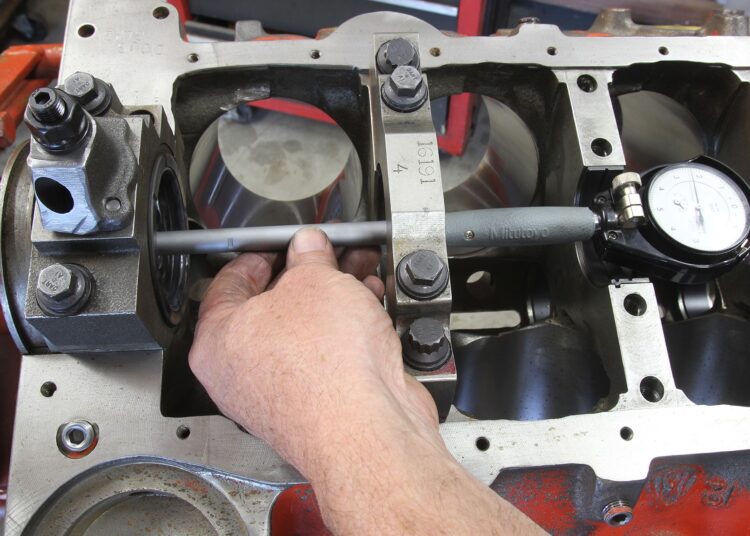

Used for taking precise measurements down to a fraction of a millimeter.

Why it matters: Crucial for matching parts to tight tolerances, especially in motor shafts and casings.

3. 3D Modeling Software (e.g., Fusion 360, SolidWorks)

Allows you to simulate, design, and visualize components before building.

Why it matters: Minimizes design errors and streamlines prototyping.

4. Soldering Station

Used for assembling electrical components like windings and PCB circuits.

Why it matters: Clean, reliable solder joints are essential in motor electronics.

5. Rotary Tool (Dremel)

Perfect for grinding, cutting, sanding, and polishing small parts.

Why it matters: Offers precision in modifying enclosures and housings.

6. Drill Press or Hand Drill

Used for consistent and accurate hole placement.

Why it matters: Essential when mounting components or creating alignment holes.

7. Lathe Machine

Used to shape motor shafts and cylindrical parts.

Why it matters: Delivers professional-level precision for rotating parts.

8. Winding Jig or Coil Winder

Automates or simplifies stator coil winding.

Why it matters: Ensures uniform windings, improving motor efficiency.

9. Torque Wrench

Tightens bolts to exact specifications.

Why it matters: Prevents over-tightening and mechanical failure.

10. Heat Gun

Useful for heat-shrink tubing and wire insulation.

Why it matters: Provides insulation and safety in compact motor builds.

Pro Tips for Tool Selection

-

Buy Quality, Not Quantity: Investing in a few high-quality tools pays off over time.

-

Modular Toolkits Are Ideal: Choose tools that offer expandability as your projects grow.

-

Ergonomics Matter: Tools that feel good in your hands reduce fatigue and improve accuracy.

Best Places to Buy DIY Motor Design Tools

-

Amazon – Wide selection, great for beginners.

-

AliExpress – Affordable for components and electronics.

-

Harbor Freight – Good for budget-friendly mechanical tools.

-

Maker-focused stores – Like SparkFun or Adafruit for electronics and sensor integration.

Bonus: Free Software for DIY Motor Designers

Maximize your performance without spending a dime on software:

-

KiCad – Free PCB design tool

-

Fritzing – Great for prototyping circuits

-

FreeCAD – Open-source 3D design software

-

EMWorks – Basic motor simulation tools for students and hobbyists

Final Thoughts

The journey of building your own motor starts with the right set of tools. Whether you’re tinkering with a simple DC motor or developing a complex BLDC (Brushless DC) system, these essential DIY tools will empower you to bring your ideas to life with precision and confidence.

Start small. Learn constantly. Upgrade wisely. That’s the formula for success in the world of DIY motor design.